About the Facility

A food processing plant specializing in delicatessen and sausage products in Morocco faced significant limescale challenges across their critical equipment.

The Challenge

- Limescale problems in steam boilers, sterilizers, and heat exchanger

- Client had to use water softener

- Sterilizers had scale built up over 15 years with no cleaning

Years of Scale

Vulcan Units

Scale Layer (Boilers)

Installation Details

Location

Facility: Food processing plant for sausage products

Location: Morocco

Type: Delicatessen food production

Vulcan Installation

Model 1: Vulcan 3000 for the boilers

Model 2: Vulcan 3000 for the heat exchanger

Model 3: Vulcan 5000 for 2 sterilizers

Installer: STE ETCT INDUSTRIE, Morocco

Installation Gallery

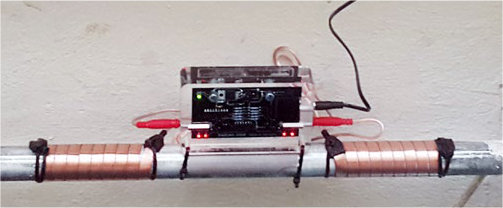

Vulcan 3000 treats the heat exchanger

Vulcan 3000 treats the steam boilers

Vulcan 5000 treats 2 sterilizers

Results by Equipment

Steam Boilers

Before: Non-stop running for more than 1 year, 0.5mm limescale layer found

After 2 months: Limescale can be removed easily by a finger

Heat Exchanger

Treatment: Vulcan 3000 installed

Result: Water softener replaced, old scale becomes soft

Sterilizers (2 units)

Before: Limescale built for 15 years, never cleaned

After 3 months: Limescale already coming out

The water softener is replaced with Vulcan and old scale becomes soft.

15 Years of Scale – Finally Removed

The sterilizers had accumulated limescale over 15 years of operation with no cleaning. After just 3 months with Vulcan 5000, scale began coming out.

Timeline:

- 15 years: Scale accumulation, no cleaning

- Installation: Vulcan 5000 on both sterilizers

- After 3 months: Scale visibly coming out

Benefits for Food Processing

Boiler Efficiency

0.5mm scale removed, easy cleaning

Sterilizer Performance

15-year scale finally removed

Water Softener Eliminated

Chemical-free solution

3-Month Results

Visible scale removal

| Max Pipe Diameter: | 1.5 inches |

| Max Water Flow: | 13 GPM |

| Wattage: | 2.0 W |

| Dimensions: | 5.1" x 3.1" x 1.2" |

| Pipe Materials: | All types |

| Maintenance: | Zero |

| Max Pipe Diameter: | 2 inches |

| Max Water Flow: | 35 GPM |

| Wattage: | 2.0 W |

| Dimensions: | 5.9" x 3.3" x 1.2" |

| Pipe Materials: | All types |

| Maintenance: | Zero |

Installation Summary

| Equipment | Model | Result Timeline |

|---|---|---|

| Steam Boilers | Vulcan 3000 | 2 months – scale removable by finger |

| Heat Exchanger | Vulcan 3000 | Water softener replaced, old scale soft |

| 2 Sterilizers | Vulcan 5000 | 3 months – 15-year scale coming out |

15 Years of Scale – Gone in 3 Months

This Moroccan food plant proves that Vulcan delivers results even on the most stubborn, decades-old scale. The sterilizers hadn't been cleaned in 15 years. After just 3 months with Vulcan 5000, scale began coming out. The water softener is history, and old scale becomes soft.

Related Food Industry Case Studies

Protect Your Food Processing Equipment

Join food manufacturers across North Africa in choosing Vulcan for chemical-free scale prevention that works on even the oldest deposits.

About the Author

Waslix provides non-chemical, maintenance-free scale prevention using Vulcan technology. This case study documents three Vulcan units (two 3000s, one 5000) protecting boilers, heat exchanger, and sterilizers at a Moroccan food processing plant, removing up to 15 years of scale.