A dairy cattle stable in Torreón, Mexico installed a Vulcan S10 on the 2" main water line. Results: boiler cleaning extended from every 45 days to easy maintenance, limescale became smooth and easy to remove.

CCI Vietnam, a global electrical components manufacturer, installed 12 Vulcan units across their factory. Results: eliminated scale inhibitor chemicals, extended chiller cleaning from 3 to 8+ months.

The Sheraton Saigon Grand Opera Hotel in Ho Chi Minh City installed two Vulcan X-Pro 1 units—one on the DN500 cooling tower line and one on the DN500 chiller line. After a year of proven performance, they added the second unit.

A leading pharmaceutical factory in Vietnam installed Vulcan X-Pro 1 on their 2000RT chiller and cooling tower system. Results after two years: cleaning frequency reduced from every 2-3 weeks to every 6 months, 100% chemical savings, and reduced electricity usage.

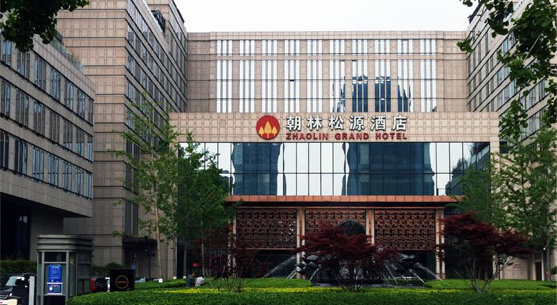

Two Zhaolin Plaza office buildings in Beijing's core business district installed Vulcan S500 units on their central air-conditioning circulating water systems. After 5 months, chemical inhibitors were completely replaced, scale fell off cooling tower packing, and the system operated stably with conductivity up to 6630 µS/cm—significantly reducing wastewater discharge.

The King Khalid Sport City Stadium in Tabuk, Saudi Arabia, installed two Vulcan S250 units on the supply and return water lines of its central air conditioning system. This chemical-free solution ensures efficient cooling for athletes and spectators while protecting critical HVAC infrastructure from mineral scale.

Page 1 of 5