The GICA Cement factory in Algeria installed a Vulcan Anti-Scale System on the make-up water line to the crusher workshop injection pump. After testing, the technical inspection team confirmed positive results.

The Energy Complex in Thailand, the first office complex in Southeast Asia to receive LEED Platinum certification, installed Vulcan S250 and X-PRO 1 units on their condenser water system. Within 4 months, they eliminated 330 lbs of monthly scale buildup, reduced chiller approach temperatures, and improved overall energy performance.

A 4 year field test of the Vulcan electronic descaler was conducted at a Mall’s cooling towers in Indonesia. During the 4 years no system maintenance was required and the system was not treated with chemicals. Mall administration and maintenance report the prevention of rust in their iron pipes has been an added benefit.

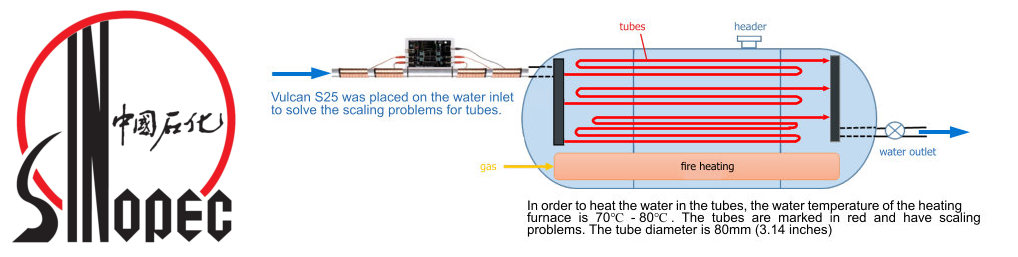

After 6 months of using the Vulcan electronic descaler the Sinopec Shengli Oilfield does not have to use chemical to manage scale build up in water heating tubes. The company saved costs in energy, labor, maintenance, and no longer deals with their heating system being compromised by heating efficiencies.

ICL Group, a global chemical manufacturer in Israel, installed a Vulcan 5000 on shower return water pipes. Results: eliminated 2-week clogging, saved full-time maintenance employee, showerheads scale-free after 2 months.

MPICO develops products for vehicle fuel efficiency and performance improvement (example: heat-resistant PET, wipers, electrical insulators, various brake devices, etc.) The descaler is used to replace their water softener for the injection molding plant pipeline equipment.

Page 1 of 2