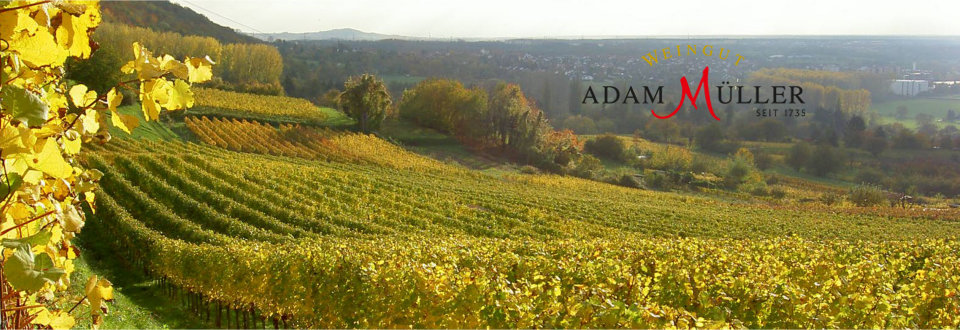

About Weingut Adam Müller

Weingut Adam Müller is a German winery located in Leimen, a town in the Baden-Württemberg region. Like all wineries, maintaining impeccable hygiene and equipment performance is essential for wine quality and production efficiency.

The winery operates a wine filling station with a cleaning machine that must operate flawlessly to ensure bottles and equipment are properly sanitized. Previously, they relied on a salt-based water softener to protect this equipment from scale. However, they made the strategic decision to replace it with Vulcan's chemical-free technology—a move that has proven successful.

m³/h Flow Rate

°dH Hardness

°C Temperature Range

From Salt-Based Softener to Chemical-Free

"For now we have used a salt-based water softener for our filling station. The hourly output of the unit is approx. 8m³ of water. The water hardness is between 25 and 28 degrees German hardness."

Previous Method

- Salt-based water softener

- Required salt purchases and maintenance

- Environmental impact of brine discharge

New Solution

- Vulcan chemical-free system

- No salt, no chemicals, no maintenance

- Environmentally friendly

- Softener stopped and dismantled

Installation Details

Location

Winery: Weingut Adam Müller

City: Leimen

Region: Baden-Württemberg

Country: Germany

Vulcan Installation

System: Water treatment system

Application: Wine filling station & cleaning machine

Flow Rate: approx. 8 m³/h

Water Hardness: 25-28 °dH

Temperature Range: 14°C - 90°C

Results: Complete Success

"We have now used your salt-free water treatment system instead of the salt-based water softener. Up to date we are very satisfied. The water treatment system fully replaces the water softener for us."

Critical Zone Performance

"We use water temperatures of 14°C - 90°C. Herewith we do not notice any scale deposits. Even in the critical zone of the cleaning machine in the area of the warm water and alkaline solution, we have not noticed any limescale deposits."

Key Outcomes

- Water softener stopped and dismantled

- No scale deposits at any temperature

- Critical cleaning machine protected

- Complete customer satisfaction

Benefits for Wineries & Beverage Production

Product Purity

No chemicals in production area

High Temperature

Effective up to 90°C

Equipment Protection

Cleaning machine stays scale-free

Softener Replacement

Eliminates salt and maintenance

Operating Parameters

| Flow Rate | approx. 8 m³/h |

| Water Hardness | 25 - 28 °dH (German hardness) |

| Temperature Range | 14°C - 90°C |

| Previous System | Salt-based water softener (now dismantled) |

| Current Status | Fully replaced |

*Login for pricing and exact specifications.

Proven Performance in Demanding Conditions

Weingut Adam Müller demonstrates that Vulcan technology can handle the demanding requirements of beverage production. With flow rates of 8 m³/h, water hardness of 28 °dH, and temperatures reaching 90°C—including the aggressive environment of alkaline cleaning solutions—the system delivers complete scale protection. The salt-based softener is gone, and the winery reports no scale deposits. This is chemical-free success in a critical industrial application.

Related Food & Beverage Case Studies

Replace Your Softener with Vulcan

Join Weingut Adam Müller and other beverage producers in choosing chemical-free scale prevention.

About the Author

Waslix (Vulcan Mineral Descaler) provides non-chemical, maintenance-free scale prevention using impulse technology. This case study documents the successful replacement of a salt-based water softener at Weingut Adam Müller in Leimen, Germany, protecting a wine filling station and cleaning machine operating at up to 90°C.